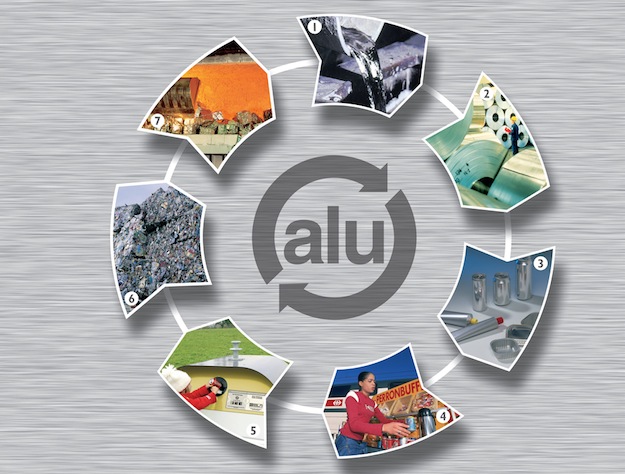

Aluminum is a material we can find in every aspects of our lives as well as in many industrial sectors. Just think of bikes, planes and trains, cars, fixtures. Just take a look around: aluminum is also in spray bottles, pots, cutlery, cans, tubes… almost everywhere. Aluminum has a high rate of recycling: 75% – primary aluminum produced in the last 125 years is still in use. One of the latest applications for recycled aluminium is in radiators and heaters. The production of the same quantity of steel would require much more energy and materials. Thanks to its pliability, aluminium can be employed in the realization and design of heating modules which become part of home furniture.

This type of radiators ensure greater energy efficency, especially where a steady and continuous operation is not required. Water contained in this kind of elements is significantly lower (28% compared to cast iron and 45% compared to steel). This results in a lower heating time and use of the boiler, i.e. reduced energy costs.

Aluminum is recycled in the foundry where waste packagings are collected in bales aan taken into care. The material is treated then at about 500°C to make sure that the adherent substances (paints, as an example) are separated and then melted at 800°C then obtaining ingots and plates for processing. Recycling and recovery brings many benefits to the environment.

Economy: in our Country there is a lack of raw materials, for this reason a material that can be recycled, retaining its properties, is an invaulable resource. In addition, in the energy field it allows a saving of 95% of the energy needed for production. Finally, recycling allows the protection of the environment.

As the Assembly of the CiAI (national Consortium for the Recovery and Recycling of Aluminium Packaging) members reported for 2015:

50,200 – tons of recovered packaging (equal to 75% of that market)

6607 – Italian municipalities where the recycling of aluminum packaging is active (88% of the Italian population)

The recycling of 46,500 tons of packaging aluminum avoided greenhouse emissions for 345 thousand tons of CO2 and saved energy for more than 148 thousand tons of oil equivalent.